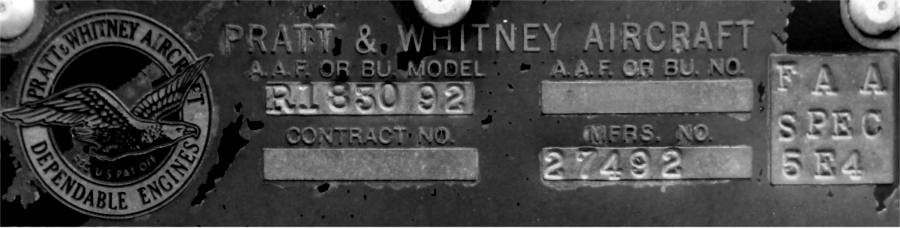

A few years ago, BAPA acquired a Pratt & Whitney R-1830 Twin Wasp engine that had previously powered C-47 N49AG (Air Dakota). The engine was damaged after running without oil pressure due to an incorrectly installed filter, leading to its decommissioning.

Partially incomplete, it remained stored until a former marine engineer joined the team and launched a long-term restoration project. The aim is not only to restore the engine for display but also to acquire hands-on experience in working with radial engines ahead of future restoration work on BAPA’s B-25 engines.

Such a project involves research and the acquisition of parts and tools.

In 2023, a set of engine tools was purchased from a former B-17 mechanic of the National Geographic Institute (France). In April 2023, an exchange with Airventure Ltd allowed us to recover many of the missing components, including a piston, an accessory case, and several parts such as a carburetor, starter, generator, magnetos, and a cylinder. We also acquired a series of R-1830 maintenance manuals.

As shown in the photos, François-Xavier carefully disassembled the engine and discovered the extent of the damage: some pistons had begun scattering metal debris throughout, and the crankshaft had completely broken.

All salvageable parts are being cleaned, refurbished, and treated for long-term preservation. The cylinders, for instance, undergo micro-abrasive blasting (aerogommage) by a specialized company, followed by anti-corrosion treatment. Meanwhile, we are still searching for missing or replacement parts for those that are too damaged. We’re also looking to complete the engine with a engine mounting. .

If anyone can help—or would like to learn how to work on this type of engine—please get in touch!

The engine as received, stored at the workshop

An exchange with Airventure Ltd allowed us to retrieve many missing parts and accessories.

Above: The accessories box acquired via an exchange after soda blasting (at left) and painted with a few of the accessories installed, the two magneto are clearly visible above the carburetor inlet.

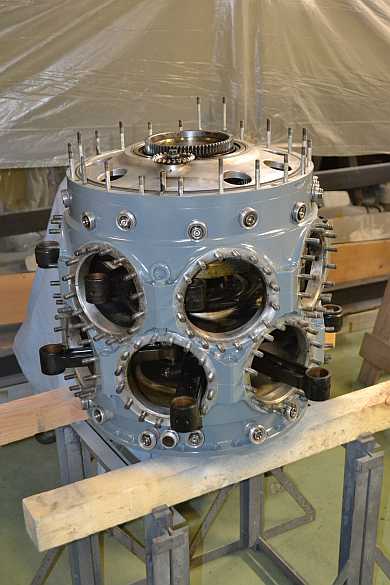

Above: All the cylinders have been removed, allowing a thourough inspection and proper cleaning of the engine. At right the reduction gearbox is in perfect condition and has been repainted after a thourough cleaning.

Above: The cylinder, dismantled and degreased,have been micro-abrasive blasted to remove the corrosion. At right wha happens in an engine with improper lubrification: some piston started to desintegrate and pieces of metal have been found everywhere in the engine, and a rod bearer is broken in two!

Above: The cylinders, after undergoing micro-abrasive blasting, have received corrosion protection and are now ready for reinstallation. The engine core has been thoroughly cleaned and repainted. Aside from a damaged connecting rod assembly, the engine core is in excellent condition. To allow reassembly, the engine stand—on which the engine was previously mounted—has been modified to accommodate the engine now fitted with its accessory gearbox.

We found many of the missing components and now have a nearly complete R-1830 in proper condition.

But we are still looking for many small (and not so small) parts to improve the exhibit.

Here is a list of spare needed to complete this engine.

If anyone can help—or would like to learn how to work on this type of engine—please get in touch!

Ref document : Parts Catalog for Twin Wasp Model R-1830-C3G & -92 Pratt & Whitney

a) ignition wire conduit and accessories

p/n : 90444 pipe – magneto to manifold conduit right hand

p/n : 90435 conduit assembly – magneto to manifold

b) rear crankcase accessories

p/n : 18480 cover – oil screen

p/n : 40989 gasket - oil screen

p/n : 20126 plug – oil screen cover

p/n : 11328 housing – vacuum pump drive

p/n : 30684 seal – vacuum pump drive

p/n : 91972 cover – vacuum pump drive

p/n : 89687 valve assembly complete

p/n : 131 plug round head -rear crankcase

p/n : 86263 pump machining assembly – rear oil

p/n : 25616 housing – fuel pump drive seal

p/n : 25618 seal – oil

p/n : 35961 cover – fuel pump drive

p/n : 12874 cover starter drive

p/n : 19865 plug – rear crankcase

p/n : 10682 bushing (reduction oil tank vent connection)

p/n : 28795 body – rear breather

p/n : 38568 pipe assembly – rear breather

p/n : 91972 cover – vacuum pump drive

p/n : 234 gasket (intermediate rear crankcase plug)

p/n : 131 plug (intermediate rear crankcase plug)

p/n : 236 gasket (supercharger fuel drain)

p/n : 85622 valve assembly -supercharger fuel drain

p/n : 88254 plate -fuel drain

p/n : 85616 shaft – fuel drain

p/n : 88282 plate – fuel drain

p/n : 85618 insert – fuel drain

f) pushroad cover tube , cylinder flange nuts

p/n 39292 cover assembly – push rod

p/n 9265 nut – push rod tube

p/n 10449 nut – plain 9/16 hex head (cylinder holddown)

g) front cylinder intake pipe, rear cylinder intake pipe (part 2, 3)

p/n : 25717 pipe assembly – front intake

p/n : 802 packing – intake pipe to blower

p/n : 90764 packing – intake pipe

p/n : 18848 pipe – rear intake

p/n : 8323 nut – rear intake pipe

p/n : 803 nut – rear intake pipe

p/n : 802 packing – intake pipe to blower

p/n : 90764 packing – intake pipe

h) Piston

p/n : 35780 piston

p/n : 55207 pin assembly- piston

p/n : 47493 plug (piston pin) x2

associated rings

i) connecting rods

p/n : 38315 rod assembly connecting

p/n : 36759 rod machining assembly - master

j) engine mount

k) propeller, complete (hub, blades, dome etc.)